Dates sterilization unit, very important part from Dates processing factory, because of their major role in the sterilization dates, and kill all insects and larvae and eggs, before starting stages of washing, cleaning and packing.

Model: AP41-CO²

The process is done emptying the chamber of the air completely, then placed Dates baskets into the room sterilization, and coordinate equal with leaving a space between the row and the other, emptying natural air from chamber, then injection carbon dioxide gas.

Should control temperature and humidity, so that they are as follows:

- Temperature: 30 ° C.

- Humidity: 50 to 60 percent.

The process will continue for 24 continuous hours, then empties gas and replaces the air naturally, this method is sterilization does not leave any negative effect on the dates and the success rate is 100%.

Model: AP41-Gas

Dates sterilization unit, an important part, of the processing manufacturer dates, for its substantial role in the sterilization dates, and kill all insects and larvae and eggs, before start stages, Washing, cleaning and packing of dates.

This unit is a concrete chamber, is usually part of the canning manufacturer dates, contain the room, entrance and only one window, within the following dimensions:

- Entrance dimensions:

- (100 × 200 cm).

- Window dimensions:

- (40 × 40 cm).

The process begins, as soon as put active substance (phosphide magnesium or aluminum), after placing dates baskets within the room and coordinate equal with leaving a space between the row and the other in the heat of the amount of 35 C above zero and the humidity between 65 to 70%, continue the operation for 48 hours straight, After 24 hours of sterilization, replaces the room air, in normal air, by the turbo fan for a period of 12 hours “This process is known the ventilation” This method is sterilization be a success rate of 100%, but they keep a percentage of the active substance on the fruits of dates, up to 3 to 4 ppm, the ratio is acceptable and does not affect the consumer’s health.

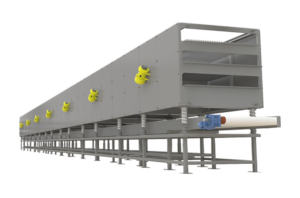

Date sterilization containers: AP41-20CO² -20 ft. / AP41-40CO² -40 ft.

Date sterilization container, sealed metal container coated internally with insulating paint, equipped with indoor lighting, temperature control equipment, humidity and oxygen ratios , The process is carried out by fully emptying the container from the air after placing the dates baskets in the container and in equal coordination with leaving a distance between the rows. The carbon dioxide is then injected to replace the empty air in a manner equal to the normal atmospheric pressure at a temperature of 30 ° C and Between 50 and 60%, the process continues for 24 consecutive hours, then the gas is discharged and replaced with natural air. This method of sterilization leaves no negative effect on the dates and the success rate is 100%.

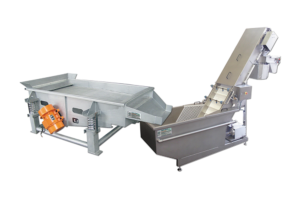

Date sterilization containers: AP41-20Gas-20 ft. / AP41-40Gas-40 ft.

Date sterilization container, sealed metal container coated internally with insulating paint, equipped with indoor lighting, temperature control equipment, humidity and oxygen ratios.The process is carried out by placing the active material (magnesium or aluminum phosphide) after placing the dates baskets inside the container and in equal coordination with leaving a distance between the row and the other. In a temperature of 35 ° C above zero and with humidity ranging from 65 to 70%, the process continues for 48 continuous hours, Gas is replaced by natural air by the turbo fan for 12 hours. This process is known as ventilation. This method of sterilization has a 100% success rate, but it keeps a percentage of the active ingredient on date grains of 3 to 4 parts per million. Public Health